Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔧 Tap into Excellence with Every Turn!

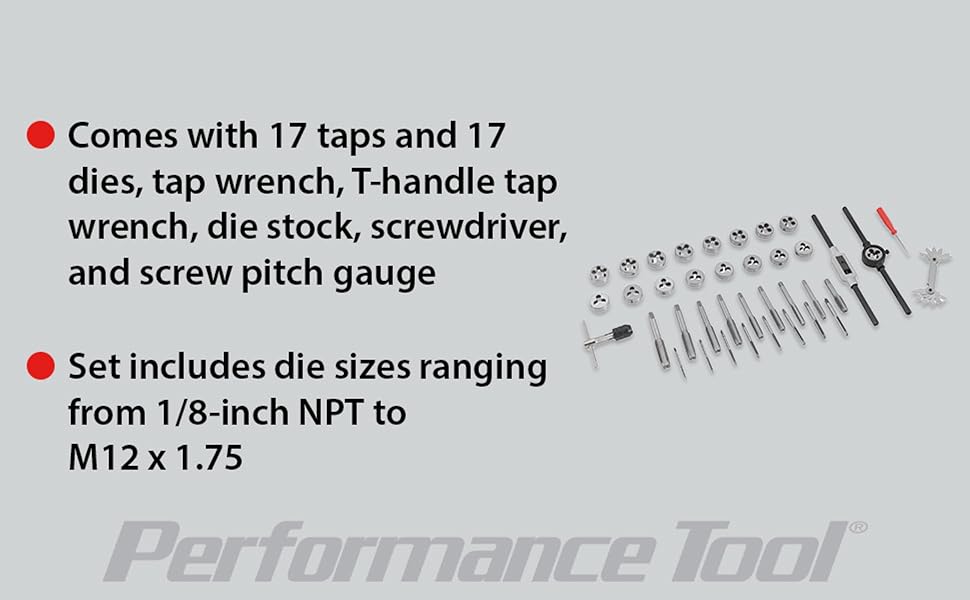

The WILMAR 40pc Metric Tap & Die Set is a premium collection designed for both professionals and DIY enthusiasts, featuring high-quality steel tools that ensure precision and durability across a variety of threading tasks.

| ASIN | B000N322BE |

| Country of Origin | USA |

| Item Dimensions LxWxH | 5.1 x 33 x 17.8 Centimeters |

| Item Weight | 1 kg 290 g |

| Item model number | W4002DB |

| Net Quantity | 1.0 Count |

| Product Dimensions | 5.08 x 33.02 x 17.78 cm; 1.29 kg |

L**L

Están muy bien fabricados, con Precisión. Aun que son para uso doméstico, son muy convenientes ! solo hay que lubricar bien y Trabajan Perfectos. Y el precio es otra conveniencia ! muy Recomendados !

A**S

When installing one of the rear toe arms into the knuckle using the bolt in the picture with the triangular washer, tragedy struck. This was the last side, so I was in the home stretch for this (terrible) job. I say terrible because the eccentric alignment bolts get SUPER seized in the toe arms here in the rust belt, requiring a ton of effort to remove said arms, and obviously new alignment bolts from the dealer as well. Both old toe arms still have part of the bolt fused to the inner metal sleeve of the bushing. Anyways, when installing this bolt into the threaded hole in the rear knuckle/hub assembly, I noticed there was a lot of lateral pressure on the bolt. Foolish me, I decided to just use my impact to zip it on to get it started. However, when tightening it with my 1/2” ratcheting wrench, I noticed the effort to screw in the bolt was WAY too high, and the bolt hadn’t even bottomed out yet. Luckily, I did the smart thing and stopped, then backed the bolt out and tightened alternatively, yet the difficulty/high torque required to tighten remained. So now alarm bells are going off in my head 🚨. I calmed down and thought that if I’m going to have to put lateral pressure on a bolt, I should do it on the other side of the toe arm, where the eccentric alignment bolt is. I later found out that this was an extremely good idea because the eccentric bolt (long thin one on the top left of the attached picture) was only threaded at the bottom 1/3. The unthreaded “shank” of the bolt is actually much better at dealing with lateral forces because the lack of threads means it is stronger, or something like that. Also, since there are no threads to turn, the high lateral force on the bolt shouldn’t affect the threads on that side. You can just turn the nut onto the bolt. I then removed both bolts completely, and started to thread on the threaded bolt with triangular washer to the knuckle (bottom bolts in the attached pic). But alas, my luck 🍀 was not to be on this cold, hard, long winter day, in my (thankfully) heated garage. The bolt would periodically become very difficult to thread in. So, eventually I was uncomfortable with the amount of force required to continue threading the bolt into the knuckle and stopped again, and removed both bolts completely to uninstall the (rear) toe arm completely. I figured out what happened was the lateral pressure along with me trying to forcefully thread in the bolt resulted in a phenomenon known as “galling” to occur. You can look it up, but essentially material transferred onto the threads, making a few threads too thick I believe. It was very difficult to see with my eyes, but I could easily feel it when tightening the bolt. I then figured My next best bet was to try to repair the threads, and I needed a 12x1.5mm tap and die, or thread chaser and die. This set was one of the few with the correct size, and it was cheap considering I would probably only use it once (at least I hope so) in my life. That’s where this set finally comes in to this review. I used a lot of lubrication and slowly “chased” the female threads in the rear hub assembly, as well as the male threads of the bolt itself with the tap and die respectively. I could feel the resistance at 2 or 3 points in the process, but when I was finally done, the bolt threaded into the knuckle super easily by hand. I then FINALLY and LUCKILY installed the hub/knuckle side of the toe arm by threading/installing this pesky triangular washer bolt into the hub. It went super smoothly this time. Of course. Crisis averted. I then spent way too long slowly forcing the eccentric bolt through the rear subframe and through the toe arm, which was difficult due to the lack of space and the lateral force making it very hard to push the long bolt all the way through. I eventually got it fully seated after maybe 20 minutes. I then installed the eccentric washer and nut, and went to get an alignment. The end.

M**Y

Bom

J**S

I bought this to help me manufacture measuring equipment with metric screws. It’s pretty complete and so far, works fine.

G**T

Nice selection

Trustpilot

3 days ago

1 month ago